HomeBuilding 2.0

Building real estate faster and more cost effectively by leveraging the next generation of design, steel based fabrication and global supply chains.

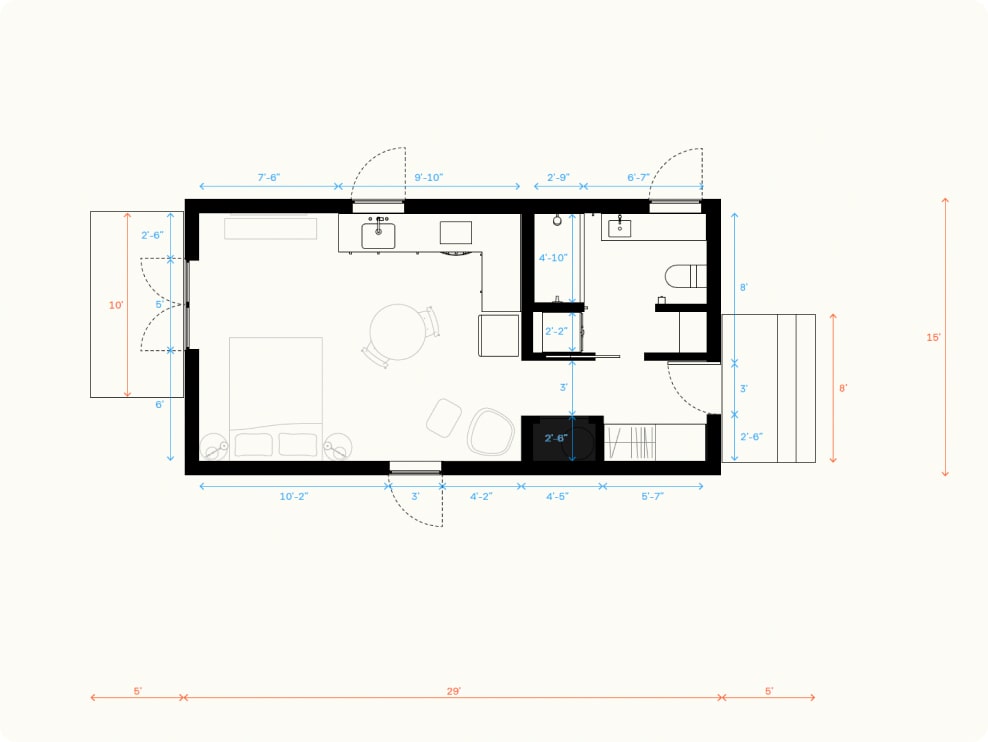

Logistics & Building Automation

Steel vs wood

Where it will help

Supply - Demand Imbalance

- Housebuilding has lagged demand

- 3-4 Million homes under built

Poor Affordability

- Low down payment savings

- High interest rates

- High student debt

ESG Challenges for Home Construction & Operation

- Material waste

- 40% of global energy use

- 33% of greenhouse gas emission

Old Construction Methods

- Long completion time

- Rising labor and material prices

- Local labor shortages

Factory Built Advantage